Product Selection

Product & System Arrangement Considerations

Whether it’s a small bearing replacement on a roller in a steel mill or a replacement of a bearing on a bridge cap, Hydraulic Technologies offers various product solutions to meet a wide array of demanding MRO applications. Utilize this section to navigate through the selection process:

STEP 1:

Application Overview - determine the type of lift or positioning equipment required for your application.

Things to consider:

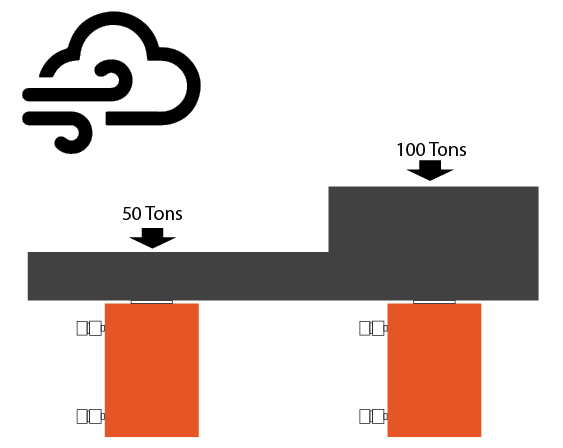

- Single or multi-point lift?

- Balance or unbalanced load?

- Guided or unguided load?

- Synchronized or unsynchronized positioning?

STEP 2:

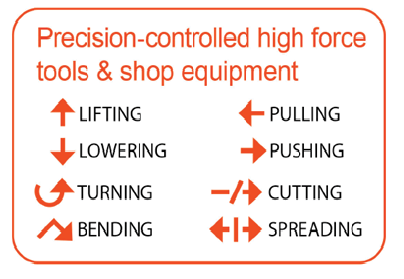

What function is required? Understanding the application movement will determine the type of pumps and tools are required.

STEP 3:

What System Components are Required? Walk through the cylinder and pump selection process

Key Points to Properly Sizing Hydraulic System

Questions to be considered:

- Total system load

- Application loading conditions

- Operating intervals

- Movement velocity requirements

- Environmental conditions

- Mounting requirements

- Pump configuration (manual or powered)

- Cylinder Movement (single or double acting)

- Return type (spring return, load return, or hydraulic return)

- Cylinder type (center hole, low height, or locking collar)

- Control options

- Automation needs (manual controlled or PLC controlled)

- System component hardware required

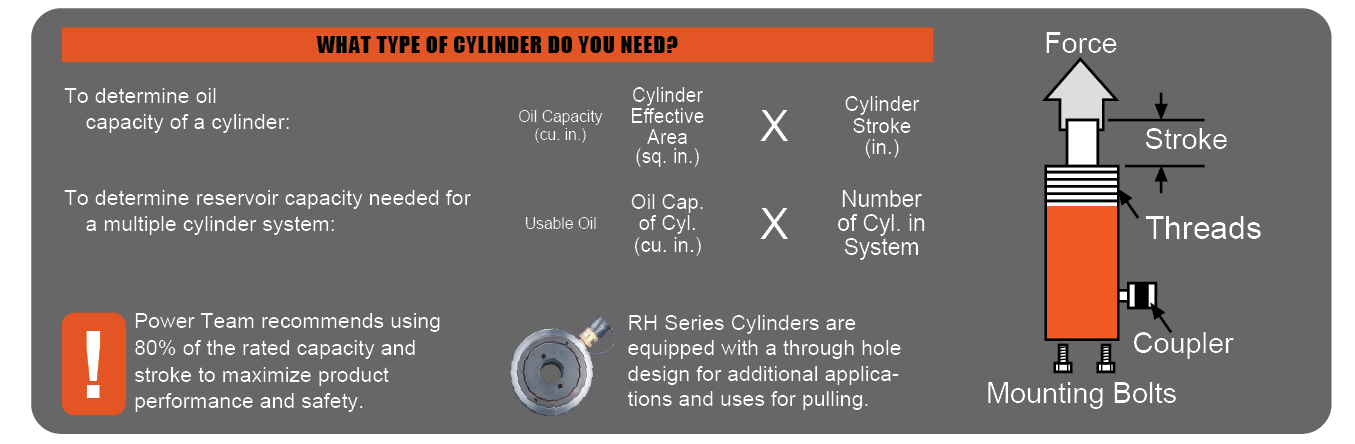

Cylinder Selection

Cylinder or Tool Type Consideration:

- Type of cylinder: Single or Double Acting

- Design Type: Spring Return, Load Return, Hydraulic Return

- Cylinder Design: Center Hole, Low Profile, or Flat Jack

- Material Type: Steel or Aluminum

- Footprint Requirement

- Lift Extension Needed

- Piston Saddle Type: Flat or Swivel Load Cap

- Handling requirements

- Tonnage Requirements

Pump Selection

Power Pump Considerations:

- What is the preferred source of power? Manual (hand or foot-operated) provides portability and can be used where electricity or shop air is unavailable. Air/Hydraulic: Uses shop air or a portable air compressor. Electric/Hydraulic: What voltage is available? Is a battery operated pump preferred?

- What maximum system operating pressure (psi) is required?

- Power or pressure control switching

What volume of oil delivery is required? (For manual pumps, cu. in. of oil per handle stroke. For powered pumps, cu. in./min. of oil). - Is a single-speed or two-speed pump required? (Two-speed pumps deliver high oil volume at low pressure for rapid cylinder piston advance and then shift to a high-pressure, low-volume stage under load.)

- Valve Control Requirements (2/3/4 Way, Manual or Solenoid)

Accessories Selection

- Hose Type (Material, lengths and ID Size should be determined)

- Manifold Requirements (what controls are required for load control)

- Fittings required?

- Couplers required?

- Gauges (Analog and digital are available)

- In-line Valve / Flow Control Requirements (Meters flow)

- Do you need remote valves? (Will the valve be used with single or double-acting cylinders?)

- Will the valve be mounted on the pump, away from the pump or directly into the hydraulic lines?

- Will the valve be manually operated, or is a remote control preferred?

Is independent control of multiple cylinders or hydraulic tools preferred?

Connect with Our Team

Complete the form and a member of our team will get back to you shortly.

Solution Development

Technical Expertise

Accurate Estimates

On-site Support

Regulatory Guidance

- 1

- 2