Compliance

Compliance and Disclosure Matters

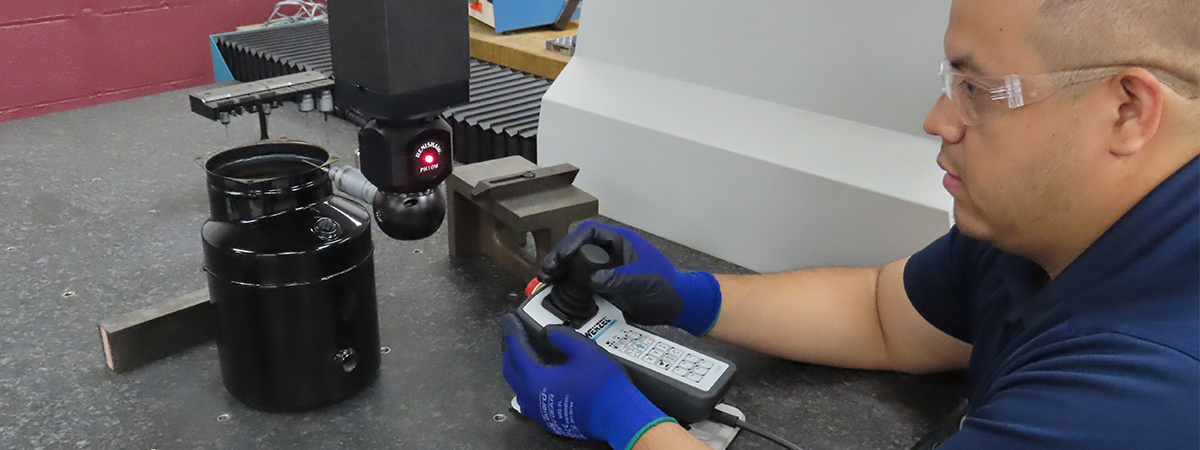

Hydraulic Technologies' commitment to quality, through our brands, is evident in everything we do, from raw material receipt to how we support our customers years after they purchase our products. Our brands are registered to ISO 9001 international quality standard, which requires compliance with standards for management, administration, product development, manufacturing, and continuous improvement.

Review

Manufacturing Standards

| ISO9001 ISO 9001 international quality standard, which requires compliance with standards for management, administration, product development, manufacturing and continuous improvement. Our registration verifies that the Hydraulic Technologies has adopted and maintains documentation for processes ranging from suppliers to customers, inspection, handling and training. ISO 9001 also requires periodic internal and external audits to ensure all aspects of work affecting quality control are monitored. |

|

| CE & UKCA Mark Hydraulic Technologies is committed to designing, manufacturing and marketing products that meet or exceed the needs of the customers we serve. Power Team supplies a Declaration of Conformity and the CE Marking / UKCA Marking for products that are within the scope and conform to at least one European Community CE Regulation or Directive, respectively a relevant UK Statutory Instrument. Note : Not all products are within such scope and subsequently may not be eligible to carry a CE / UKCA mark. In such cases and if a confirmation regarding the safety and/or applicability of the product is requested, please contact the factory for clarification (e.g. Manufacturer Declaration). Please note that such a request must be submitted at the time a product is ordered. |

|

| CSA Where specified in our literature and catalogs and on our web site, Power Team electric power pump assemblies meet the design, assembly and test requirements of the Canadian Standards Association. Note: If CSA certification is required, it must be requested at the time a Power Team pump is ordered. |

.webp?width=116&height=200&name=CSA%20(1).webp)

|

|

LRQA and RISQS |

|

ISO9001

ISO 9001 international quality standard, which requires compliance with standards for management, administration, product development, manufacturing and continuous improvement. Our registration verifies that the Hydraulic Technologies has adopted and maintains documentation for processes ranging from suppliers to customers, inspection, handling and training. ISO 9001 also requires periodic internal and external audits to ensure all aspects of work affecting quality control are monitored.

CE & UKCA Mark

Hydraulic Technologies is committed to designing, manufacturing and marketing products that meet or exceed the needs of the customers we serve. Power Team supplies a Declaration of Conformity and the CE Marking / UKCA Marking for products that are within the scope and conform to at least one European Community CE Regulation or Directive, respectively a relevant UK Statutory Instrument. Note : Not all products are within such scope and subsequently may not be eligible to carry a CE / UKCA mark. In such cases and if a confirmation regarding the safety and/or applicability of the product is requested, please contact the factory for clarification (e.g. Manufacturer Declaration). Please note that such a request must be submitted at the time a product is ordered.

CSA

Where specified in our literature and catalogs and on our web site, Power Team electric power pump assemblies meet the design, assembly and test requirements of the Canadian Standards Association. Note: If CSA certification is required, it must be requested at the time a Power Team pump is ordered.

.webp?width=145&height=250&name=CSA%20(1).webp)

LRQA and RISQS

Design, manufacture, in-house service and repair of critical electrical, mechanical and hydraulic rail infrastructure and signaling interface equipment, including point actuation machines and level crossing systems.

ASME B30.1 and ASME B40.1

Hydraulic cylinders comply with the criteria set forth in the American Society of Mechanical Engineers standard ASME B30.1: Cylinders are tested at 125 percent of rated pressure at full travel and are inspected to assure functionality and freedom from leaks.

Pressure gauges are designed in accordance with the recommendations set forth in the American Society of Mechanical Engineers standard ASME B40.1, Grade B.

Compliance FAQs:

Hydraulic Technologies is committed to maintaining high-quality and safety standards in all our products and services. We adhere to industry-specific compliance standards and regulations to ensure our offerings meet or exceed customer expectations. For detailed information on our compliance standards, please visit our Compliance page.

We implement rigorous quality control processes throughout our manufacturing and service delivery operations. This includes regular inspections, testing, and adherence to recognized quality management systems to ensure that all products and services are safe and reliable. Learn more about our quality assurance practices on our Compliance page.

Yes, Hydraulic Technologies holds several industry certifications that validate our commitment to quality and compliance. These certifications are awarded by recognized authorities and are periodically reviewed to ensure ongoing compliance. For a comprehensive list of our certifications, please refer to our Compliance page.

We actively monitor and analyze changes in industry regulations and standards. Our compliance team regularly participates in training and industry forums to stay informed about new requirements. This proactive approach allows us to adapt our processes and maintain compliance effectively. More information about our compliance strategy is available on our Compliance page.

Customers can verify the compliance status of our products by reviewing the certifications and compliance documents available on our website. We provide detailed information about each product's compliance status, including relevant certifications and standards met. For more information, contact our Technical Support team.

Yes, we conduct regular internal and external audits to assess our compliance with industry standards and regulations. These audits help identify areas for improvement and ensure that our operations remain aligned with current compliance requirements. Learn more about our audit processes on our Compliance page.

Connect with Our Team

Complete the form and a member of our team will get back to you shortly.

Solution Development

Technical Expertise

Accurate Estimates

On-site Support

Regulatory Guidance

- 1

- 2