Hydraulic Technologies for Manufacturing

Providing the Power, Precision, and Reliability Required to Keep Equipment Running Smoothly

Hydraulic tools are essential in industrial applications and for maintenance, repair, and operations (MRO) needs due to their versatility, power, and efficiency.

Driving Efficient Operations in Industrial Facilities

In industrial settings, hydraulic tools are utilized for a wide range of tasks, including heavy lifting, material handling, and assembly operations. Hydraulic presses, for instance, are used to form and shape metal components with precision and force, crucial in manufacturing industries such as automotive and aerospace. Hydraulic cylinders provide the strength needed to operate heavy machinery and equipment, while hydraulic torque wrenches enable the safe and efficient tightening and loosening of bolts and fasteners in industrial machinery and infrastructure. The ability of hydraulic tools to generate immense force using fluid pressure makes them ideal for applications where mechanical or manual methods are insufficient or impractical.

In MRO activities, hydraulic tools are ideal for maintaining and repairing a variety of equipment and infrastructure across industries. Hydraulic jacks and lifts are commonly employed for lifting and supporting heavy machinery during maintenance procedures, providing stability and safety for technicians. Moreover, hydraulic tools offer the advantage of compact size and portability, allowing technicians to access confined spaces and remote locations for maintenance and repair tasks.

Overall, hydraulic tools are assets for industrial operations and MRO needs, providing the power, precision, and reliability required to keep equipment running smoothly and ensure the efficient operation of industrial facilities.

Featured Projects in Manufacturing

MANUFACTURING / power team / manifolds

Plant Maintenance

Situation: A processing facility needed to lift a large kiln for maintenance.

Solution Supplied: LM4S lifting manifold, PE553 pump, 4 RA1006 cylinders.

MANUFACTURING / power team / shop equipment

High-Force Press

Situation: A customer needed a modified shop press to allow them to test products after being machined.

Solution Supplied: A custom-engineered 25T shop press was provided, along with an RT172 twin cylinder, a 9042DG digital gauge, a PE172 pump, and hoses.

MANUFACTURING / power team / Shop Equipment

Lime Production

Situation:

At a lime production facility in Utah, reliability is critical. The plant operates in extreme industrial conditions (high temperatures, abrasive dust, and heavy mechanical loads) through intensive processes like crushing, calcination, and hydration. Equipment failure in this rugged environment could mean costly downtime and safety risks.

Solution:

To meet these demanding conditions, this facility relies on Power Team. From hydraulic pumps and cylinders to heavy-duty shop equipment, Power Team tools deliver the durability and performance needed to maintain heavy machinery and perform critical lifts. Engineered for high-stress environments, these solutions help minimize downtime and maintain smooth, efficient production, proving their strength where it counts most.

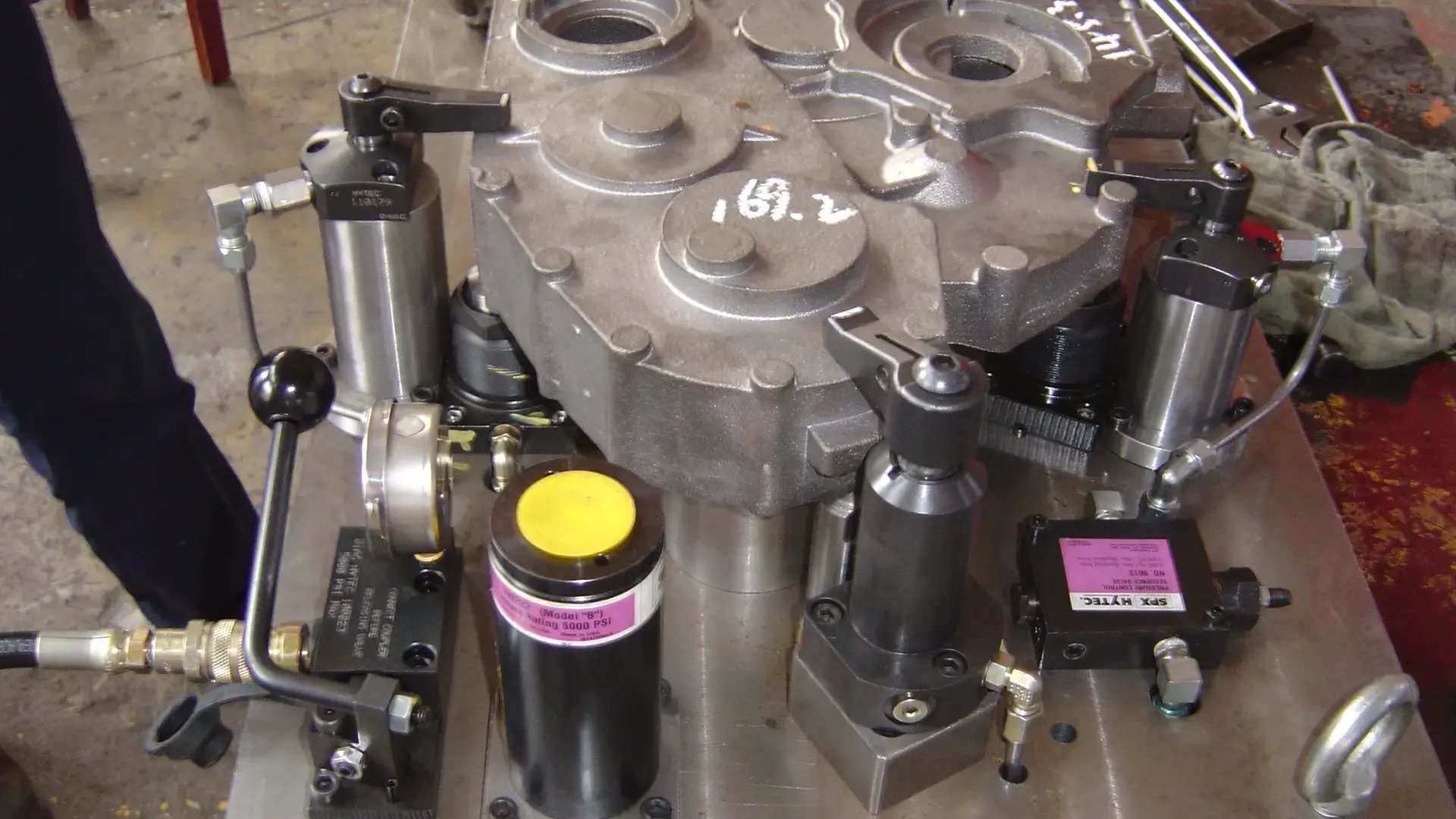

MANUFACTURING / hytec workholding / workholding

Workholding Automation

Situation: A milling application required a custom arrangement of workholding products to hold castings in place during machining operation.

Solution Supplied: A 100222 accumulator, 100223 manual pallet valve, and several work supports were configured to meet customer requirements.

MANUFACTURING / hytec workholding / workholding

Workholding Fixturing Solution

Situation: Customer required a custom fixture for their machining center to securely hold raw material during machining operation to reduce scrap rate.

Solution Supplied: A Hytec Workholding item number 100222 accumulator and 100839 die clamp were used.

Manufacturing FAQs:

Hydraulic tools are essential due to their versatility, power, and efficiency, making them ideal for tasks like heavy lifting, material handling, and assembly operations in industrial settings.

Hydraulic tools, such as jacks and lifts, are commonly used in MRO activities to lift and support heavy machinery during maintenance, providing stability and safety for technicians.

Hydraulic tools are compact and portable, allowing technicians to access confined spaces and remote locations for maintenance and repair tasks that would be difficult with mechanical or manual methods.

Hydraulic tools provide the power, precision, and reliability required to maintain and repair industrial equipment, ensuring smooth and efficient operations and minimizing downtime.

Connect with Our Team

Complete the form and a member of our team will get back to you shortly.

Solution Development

Technical Expertise

Accurate Estimates

On-site Support

Regulatory Guidance

- 1

- 2