Hydraulic Technologies for Mining

The harsh and demanding conditions of mining operations necessitate the use of robust and reliable hydraulic tools and equipment for servicing and maintenance tasks.

Mining equipment such as excavators, haul trucks, and drills operate in challenging environments characterized by extreme temperatures, heavy loads, and abrasive materials. Regular maintenance and servicing are essential to ensure the continued functionality and longevity of these assets.

Tools that Withstand the Rigors of Mining Operations

Hydraulic tools offer the strength and durability required to perform maintenance tasks effectively in such environments. Their ability to withstand the rigors of mining operations ensures that maintenance procedures can be carried out efficiently without compromising on safety or performance. Furthermore, the versatility and efficiency of hydraulic equipment make it indispensable for servicing and maintaining mining machinery.

Hydraulic systems power a wide range of tools, including wrenches, jacks, and pumps, which are essential for tasks such as component replacement, lubrication, and hydraulic system maintenance. The precise control and power provided by hydraulic tools enable technicians to carry out maintenance procedures with accuracy and speed, minimizing downtime and optimizing equipment performance.

Additionally, the compact and portable nature of hydraulic equipment allows for easy access to confined spaces within mining machinery, ensuring comprehensive servicing without the need for extensive disassembly. Overall, the use of hydraulic tools and equipment for servicing and maintenance in mining applications is crucial for maximizing equipment uptime, reducing operational costs and ensuring the safety of personnel.

Featured Projects in Mining

MINING / power team / mcs

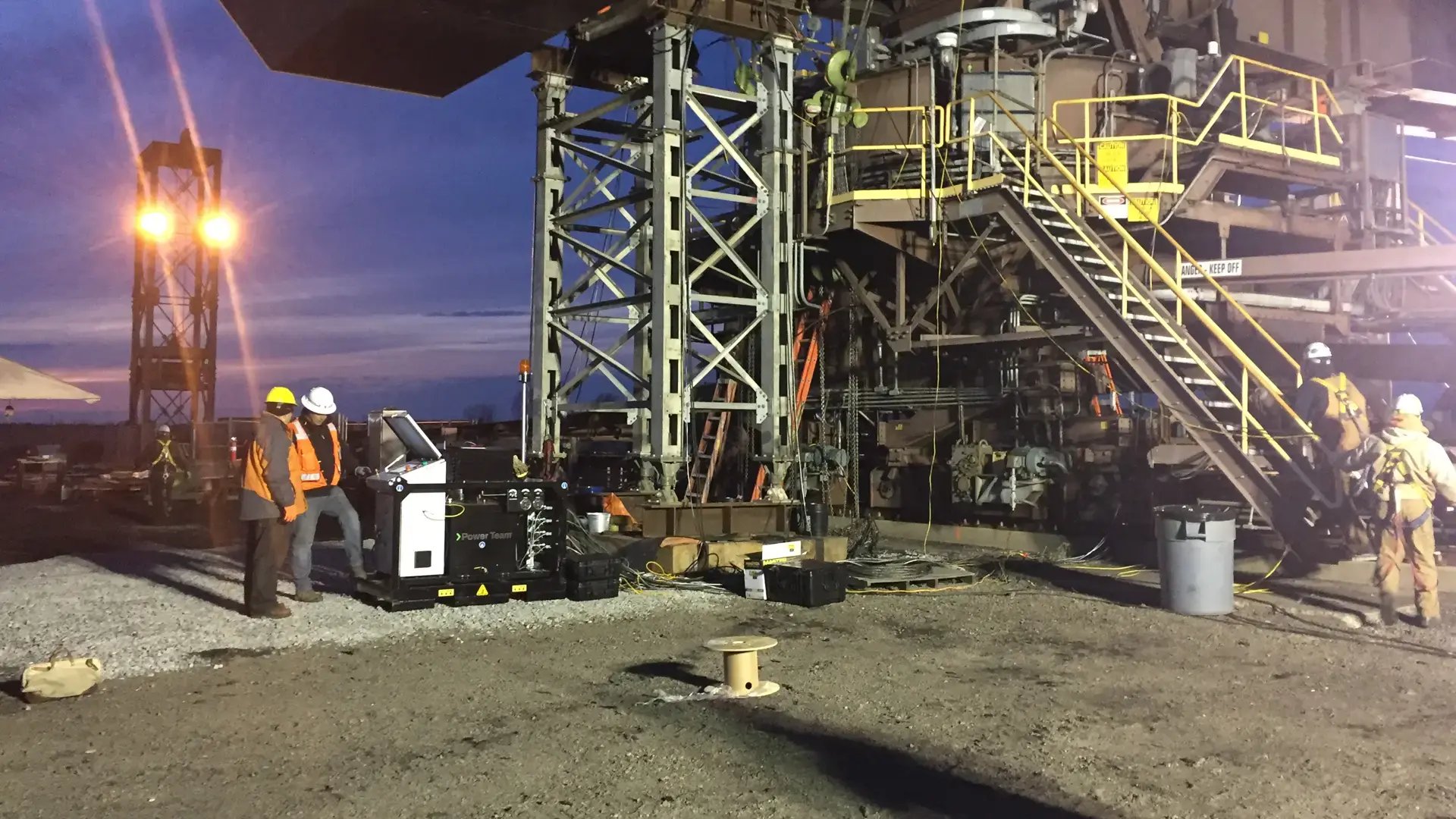

Stacker / Reclaimer Maintenance

Situation: Power plant needed to replace a worn slew bearing on a 240T Stacker/Reclaimer within a narrow tolerance to precisely lift and separate the turret to service the bearing.

Solution Supplied: 8 RD1006, 8-point MCS

MINING / power team / cylinders

Ship Loader Slew Bearing Maintenance

Situation: A mining operation was planning scheduled bearing maintenance of a ship loader. A controlled lifting and support plan was needed, as the project could only take five days.

Solution Supplied: Three R28010L cylinders and one R28010D cylinder were used in conjunction with an 8-point MCS, valves, and hoses for the lifting and holding of the ship loader. Four TWLC4 torque wrenches and torque wrench pumps were used for loosening and tightening the bolts securing the bearing in place.

MINING / posi lock / Pullers

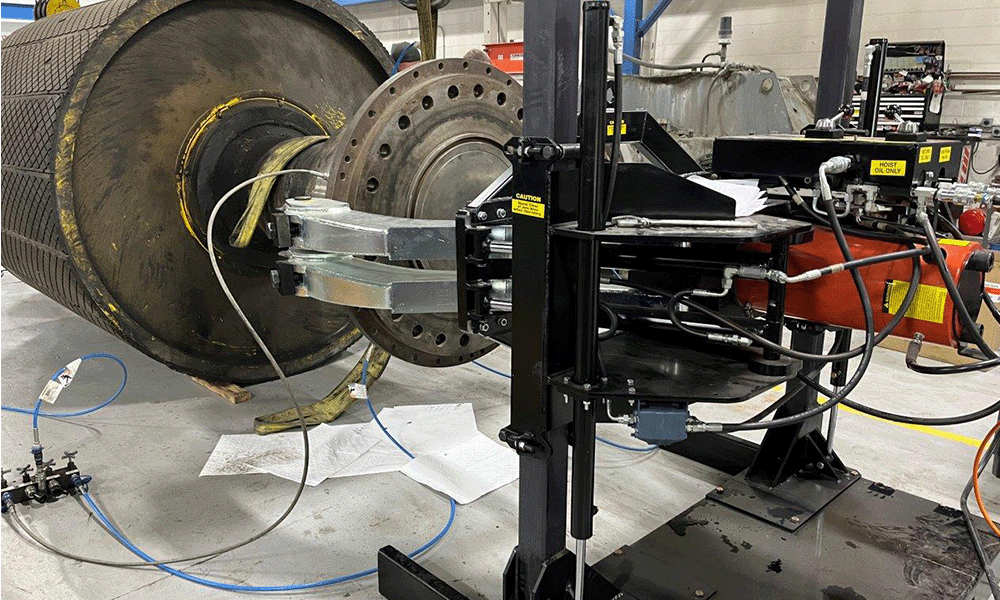

Conveyor Roller Maintenance

Situation: A customer needed to pull two large pulley hubs from a conveyor in a mining application.

Solution Supplied: By selecting the PTHT-200T hydraulic puller, the customer was able to win the service contract and ensure the conveyor was up and running, avoiding costly downtime and promoting safety.

MINING / power team / Jacks

Mining Haul Truck Wheel Service

Situation: Large mining haul trucks require tire maintenance.

Solution Supplied: RJ100T37E self-contained jacking system to safely lift and lower the mining haul truck into position during routine tire replacement.

Mining FAQs:

Hydraulic tools are crucial in mining operations because they offer the strength and durability needed to perform maintenance tasks efficiently, ensuring safety and performance even in harsh environments.

Hydraulic tools commonly used in mining include wrenches, jacks, pumps, and other equipment essential for tasks such as component replacement, lubrication, and hydraulic system maintenance.

Hydraulic tools provide precise control and power, enabling technicians to perform maintenance procedures quickly and accurately, minimizing downtime and optimizing equipment performance.

The compact and portable nature of hydraulic equipment allows for easy access to confined spaces, enabling comprehensive service of mining machinery without the need for extensive disassembly.

Hydraulic tools enhance safety by providing efficient, controlled, and precise maintenance, reducing the risk of accidents during equipment servicing and ensuring that tasks are completed securely.

Connect with Our Team

Complete the form and a member of our team will get back to you shortly.

Solution Development

Technical Expertise

Accurate Estimates

On-site Support

Regulatory Guidance

- 1

- 2