Hydraulic Technologies for the Rail Industry

Tools and Machinery for Repairing and Servicing Tracks, Switches, and Other Infrastructure Components

The deployment of track switching devices, barriers, and hydraulic service equipment is essential for the safe and efficient operation of rail systems, enhancing transportation networks and promoting economic growth and mobility.

Supporting Safety and Enabling Efficiency

High-quality track switching devices and barriers are indispensable for the safe operation of railway systems, as they form the backbone of railway infrastructure. Track switching devices must meet rigorous standards to ensure precise alignment and reliable performance under various operating conditions. Any malfunction or failure in these devices could lead to derailments, collisions, and other catastrophic accidents.

Similarly, barriers serve as critical safety measures to prevent unauthorized access to the tracks and safeguard pedestrians and vehicles from potential dangers. Inferior quality barriers may not withstand the forces exerted by oncoming trains or withstand environmental factors, compromising their effectiveness and putting lives at risk.

Hydraulic service equipment further supports the maintenance of rail systems by providing the necessary tools and machinery for repairing and servicing tracks, switches, and other infrastructure components. This equipment enables maintenance crews to perform routine inspections, repairs, and upgrades efficiently, minimizing downtime and ensuring the reliability and longevity of rail networks.

Featured Projects in Rail

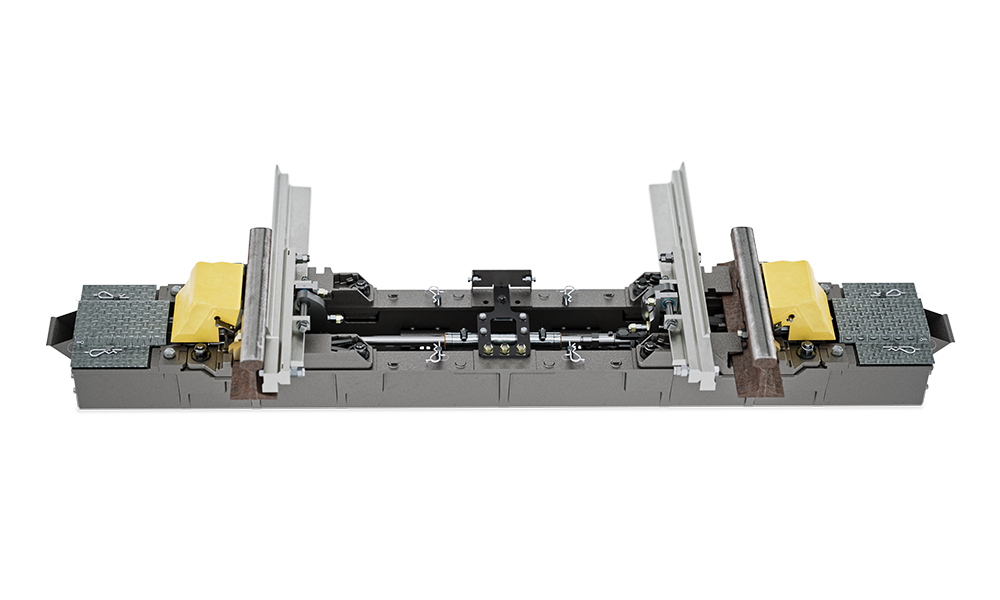

RAIL / rail systems / Point operation

Rail Track Switching

Situation: A rail customer was in search of a new point operating clamplock system that could reduce maintenance time and extend mean time between service and failures.

Solution Supplied: The MK3 clamplock was designed and approved for use by addressing customer pain points and eliminating common failures.

RAIL / power team / Pullers

Rail Car Wheel Truck Service

Situation: Rail shop was seeking a quick and safe removal of rail truck bearings. The process of removing a bearing was taking over an hour of manual work time for two employees, and the customer needed this process to be quicker and more efficient.

Solution Supplied: The use of PR3100J railroad bearing puller has shortened the effective time of removing the bearing to a total of ten minutes. The entire process now can be also performed by one person, reducing manpower requirements.

RAIL / power team / jacks

Emergency Wheel Truck Service

Situation: A railroad service yard needed a way to remotely lift railcars safely to allow service work to be completed.

Solution Supplied: A RJ100T37E rail jack was supplied to allow the safe lifting of the railcars.

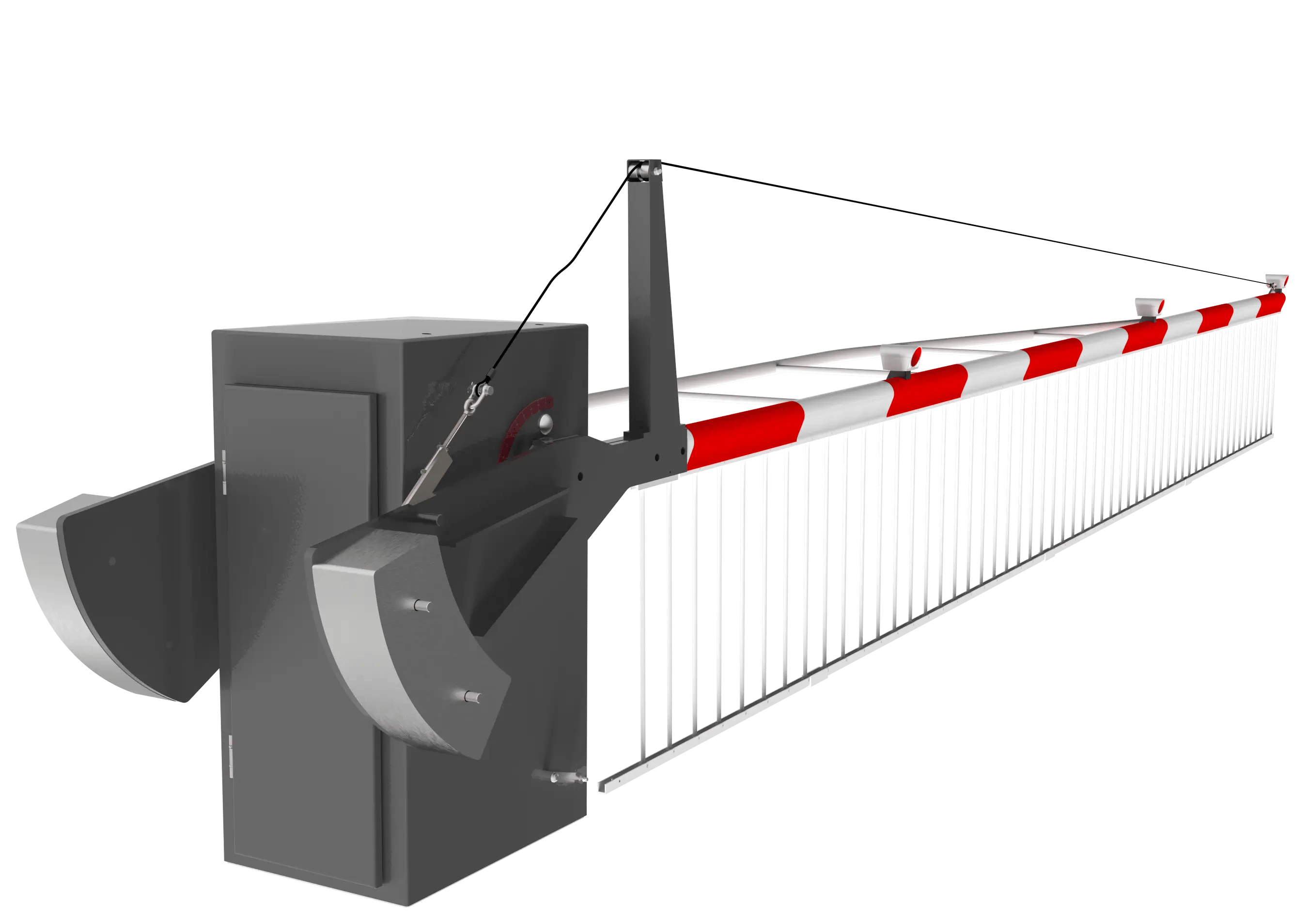

RAIL / rail systems / barriers

Level Crossing Barriers

Situation: A rail system provider needed a range of level crossing barriers to be used at various rail crossings (road and pathways).

Solution Supplied: The MK2 barrier range offered the best solution for safe, reliable performance.

Rail FAQs:

Track switching devices are essential for ensuring precise alignment and reliable performance of rail systems. Any malfunction or failure could lead to derailments, collisions, and other dangerous accidents.

Barriers are critical safety measures that prevent unauthorized access to the tracks and protect pedestrians and vehicles from potential dangers posed by oncoming trains.

Track switching devices are designed to meet rigorous standards that ensure they function accurately and reliably, even under challenging operating conditions, to maintain safe and efficient rail operations.

Inferior quality barriers may not withstand the forces exerted by oncoming trains or environmental conditions, which could compromise their effectiveness and jeopardize safety.

Proper maintenance equipment helps crews perform routine inspections, repairs, and upgrades efficiently, enhancing the reliability and lifespan of the rail infrastructure.

Connect with Our Team

Complete the form and a member of our team will get back to you shortly.

Solution Development

Technical Expertise

Accurate Estimates

On-site Support

Regulatory Guidance

- 1

- 2