Intro to Hydraulics 101

Introduction to Hydraulics

Key Terms:

- Hydraulic Fluid: The liquid used in hydraulic systems to transmit power.

- Pressure: The force exerted by the fluid per unit area.

- Flow Rate: The volume of fluid that moves through a system in a given time.

Basic Principles of Hydraulics

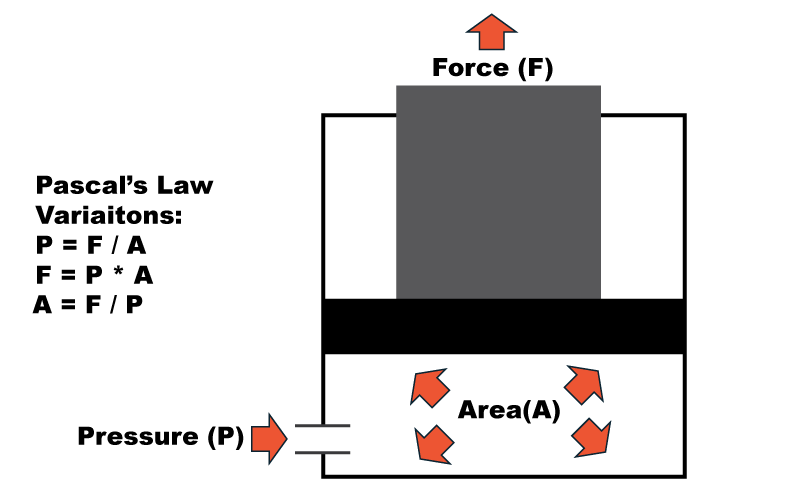

Pascal's Law - Pascal's Law states that when pressure is applied to a confined fluid, the pressure change occurs throughout the fluid in all directions. This principle is the foundation of hydraulic systems and allows small forces to be amplified into larger forces.

Example: In a hydraulic press, a small force applied to a small piston generates a larger force than a larger piston due to the equal distribution of pressure.

Force and Area - The relationship between force, pressure, and area is critical in hydraulics:

Pressure (P) = Force (F) / Area (A)

Therefore, Force = Pressure × Area

This relationship shows how increasing the area of a piston will amplify the force exerted by the fluid.

Critical Components of Hydraulic Systems

- Cylinder - A hydraulic cylinder is a mechanical device that converts hydraulic energy into linear motion. It consists of a cylinder body, piston, and seals.

Pump - A hydraulic pump (or prime mover) converts mechanical energy into hydraulic energy by moving hydraulic fluid. Common pump types include manual, electric, air, gas, and battery/cordless pumps. - Valves - Valves control the flow and direction of hydraulic fluid within a system. Common types include: Directional Control Valves: Control the path of fluid flow.

- Pressure Relief Valves - Protect the system from excessive pressure.

- Shut-Off Valves - Regulates the flow of fluid to or from cylinders.

- Load-Lowering Valves - allows metered lowering of cylinders and provides safety when prolonged load holding is required.

- Gauges - Measures pressure and/or force.

- Quick Coupler—When separated, “hose half” and “cylinder half” couplers are used for quick connection and fluid flow check.

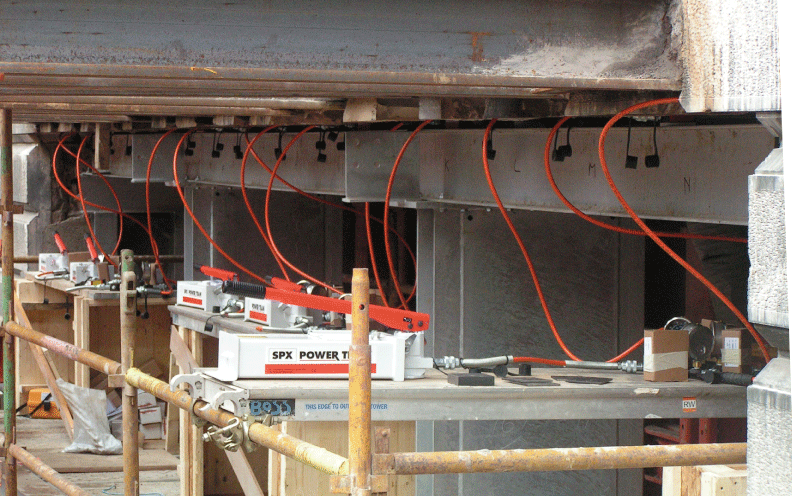

- Hydraulic Hoses - These transport hydraulic fluid between components and must be able to withstand high pressure without leaking or bursting.

Applications of Hydraulics

- Construction:

- Infrastructure

- Mining

- Energy

- Rail

- Manufacturing

- Transportation

- Aerospace

Advantages of Hydraulics

- High power-to-weight ratio

- Precise control of motion

- Ability to lift heavy loads with minimal input force

Things to Reflect

Understanding the basics of hydraulic principles is essential for anyone working with hydraulic systems. By grasping concepts like Pascal's Law, the relationship between force and area, and the key components of hydraulic systems, you can effectively apply this knowledge in practical situations.

Questions to consider:

How does Pascal's Law apply in everyday hydraulic systems?

What are some advantages of using hydraulics over mechanical systems?

Can you identify any hydraulic systems you interact with regularly?